Food processing machinery works hard behind the scenes. Mixers, conveyors and other equipment face continuous use, repeated cleaning and tough hygiene requirements. In this blog post from Australian Surface Technologies, we’ll take a look at how hard chrome plating can enhance both the durability and sanitation of food industry equipment, and why hard chrome engineering is becoming a trusted choice for manufacturers looking to minimise downtime and extend the life of their machinery.

Why Food Processing Equipment Needs Extra Protection

Food machinery is constantly exposed to moisture, cleaning agents and repetitive use, which creates the perfect conditions for corrosion and surface damage if the right protections aren’t in place. Once cracks, pits or rough textures form, bacteria can lodge in those crevices, making cleaning less effective and compliance harder to maintain. That’s why surfaces that stay smooth and resistant to wear are so important in food production. When businesses take steps to protect components from mechanical and chemical stress, they can prevent unnecessary breakdowns and keep equipment safe for use in highly regulated environments.

The Role of Hard Chrome Plating in Hygiene and Durability

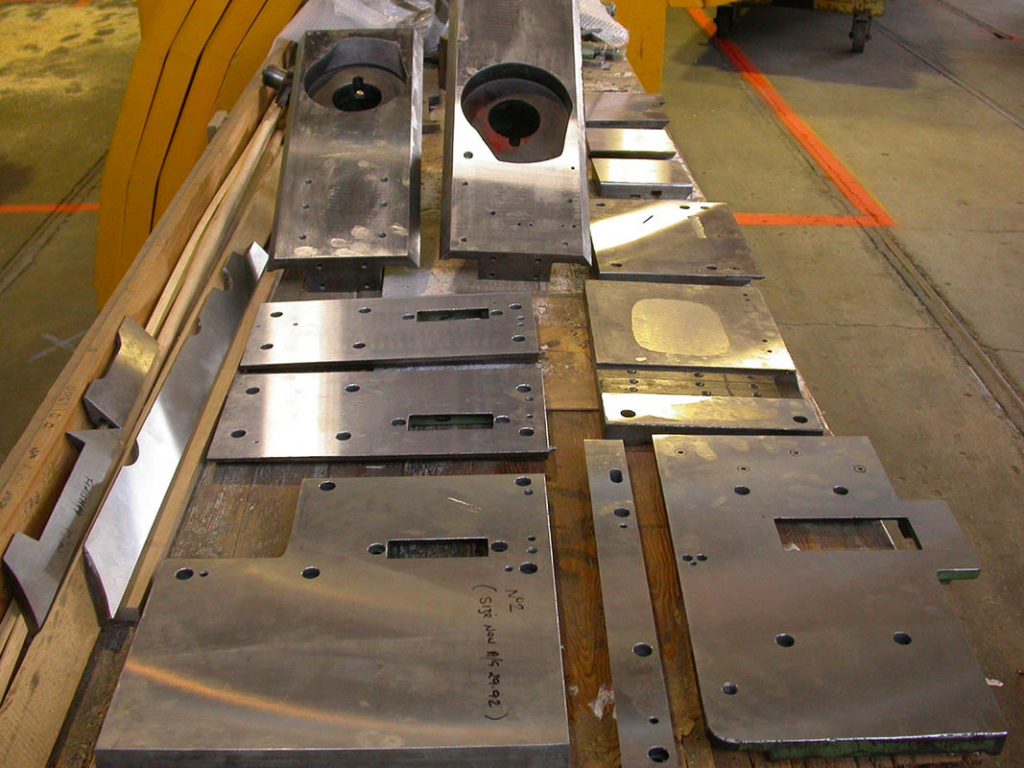

Hard chrome plating provides a dense, durable coating that bonds tightly to the base material of equipment. When applied to food processing machinery, chrome creates a smooth, non-porous surface that makes thorough cleaning easier. This reduces the risk of contamination, helping equipment stay compliant with hygiene regulations. At the same time, it helps mixers, conveyors and rollers withstand years of wear without developing scratches or grooves that could harbour bacteria.

The Key Benefits of Hard Chrome Engineering for the Food Industry

Investing in hard chrome engineering goes beyond basic protection, delivering a range of benefits that directly impact productivity and compliance:

- Surfaces better resist corrosion from detergents and sanitisers

- Smooth finishes allow for easy cleaning and food safety standards

- Extended lifespan for critical components

- Reduced downtime due to less frequent repairs or replacements

- Consistency in performance, even under heavy use

For manufacturers, these benefits mean improved reliability and fewer disruptions on the production floor.

Compliance Made Easier

Food safety regulations require machinery to meet strict cleanliness standards, and failure to comply can result in costly interruptions or product recalls. Hard chrome plating supports compliance by making surfaces less likely to develop micro-damage that traps bacteria. The smooth coating also stands up to repeated cleaning cycles without degrading, allowing equipment to maintain its sanitary condition over time.

Extending the Life of Mixers, Conveyors and More

The cost savings are just as valuable as the hygiene benefits. By cutting down on wear, chrome-coated components last longer and require less upkeep, which means machinery like mixers, conveyors and rollers can continue operating reliably without the expense or hassle of premature replacements. Over time, this durability translates into real financial gains, especially in large-scale food production where equipment is in constant use.

Talk to Australian Surface Technologies About Protecting Your Food Processing Equipment

At Australian Surface Technologies, we understand the pressures faced by food manufacturers. That’s why we provide hard chrome plating and hard chrome engineering services designed to boost durability, maintain hygiene and support compliance with food safety standards. Get in touch with our team today to find out how we can keep your machinery running smoothly and safely.